As a result of this unfavorable outcome information, the company may consider using cheaper labor, changing the production process to be more efficient, or increasing prices to cover labor costs. Knowing that variable manufacturing costs were $181,500 over budget is helpful, but it doesn’t isolate the production issue or issues. Therefore, the next step is to individually analyze each component of variable manufacturing costs.

Video Illustration 8-1: Standard costs for manufacturing costs

The articles and research support materials available on this site are educational and are not intended to be investment or tax advice. All such information is provided solely for convenience purposes only and all users thereof should be guided accordingly. The company does not want to see a significant variance even it is favorable or unfavorable. Standard costs are cost targets used to make financial projections and evaluate performance. A cost formula is used to predict the expected cost for a specific expenditure. Efficiency variance calculations not only apply to the output of tangible goods, but they also apply to the completion of cerebral tasks, such as the number of hours it takes to audit an individual’s tax records.

- These standards are compared to the actual quantities used and the actual rate paid for variable manufacturing overhead using the same processes applied in previous sections to analyze direct materials and direct labor.

- Any variance between the standard amounts allowed and actual amounts incurred should be investigated.

- This is an unfavorable outcome because the actual rate per hour was more than the standard rate per hour.

- At first glance, the responsibility of any unfavorable direct labor efficiency variance lies with the production supervisors and/or foremen because they are generally the persons in charge of using direct labor force.

- Only recurring processes benefit from tracking this variance; in cases when commodities are produced infrequently or over a lengthy period of time, tracking this variance serves little purpose.

Direct Labor Variances FAQs

It’s thus typical for management personnel to set expectations and benchmarks for both costs and output, while the manufacturing activity is still in its planning stage before the production process even starts. Efficiency variance is the difference between the theoretical amount of inputs required to produce a unit of output and the actual number of inputs used to produce the unit of output. The expected inputs to produce the unit of output are based on models or past experiences.

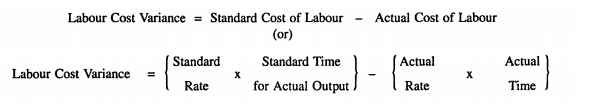

Total Direct Labor Variance

Favorable variance means that the actual time is less than the budget, so we need to reassess our budgeting method. When we set the budget too high, it will impact the total cost as well as the selling price. To arrive at the total cost per unit, we need to multiply the unit of material and labor with the whats the difference between a sales order and an invoice standard rate. It is the estimated price of material and labor that a company need to pay to supplier and workers. Variable overhead efficiency variance refers to the difference between the true time it takes to manufacture a product and the time budgeted for it, as well as the impact of that difference.

A positive value of direct labor efficiency variance is obtained when the standard direct labor hours allowed exceeds the actual direct labor hours used. A negative value of direct labor efficiency variance means that excess direct labor hours have been used in production, implying that the labor-force has under-performed. As with direct materials variances, all positive variances areunfavorable, and all negative variances are favorable. The direct labor variance is the difference between the actual labor hours used for production and the standard labor hours allowed for production on the standard labor hour rate. An unfavorable labor efficiency variance signifies that more labor hours were expended than the predetermined standard for the production achieved.

Do you own a business?

Brad invented NoTuggins, a revolutionary dog harness that stops dogs from pulling when connected to a leash by humanely redistributing the dog’s pulling force. NoTuggins was featured as the most innovative new harness by the International Kennel Association. Although the product was selling well, product costs were higher than expected, translating into lower profits. Brad decided to conduct a standard costs variance analysis to see if he could isolate the issue, or issues. The standard costs to make one unit of NoTuggins and the actual production costs data for the period are presented in Exhibit 8-1 below. The standard direct labor hours allowed (SH) in the above formula is the product of standard direct labor hours per unit and number of finished units actually produced.

A decrease in labor productivity is indicated by a negative variance, whereas an increase is shown by a positive variance. If the company fails to control the efficiency of labor, then it becomes very difficult for the company to survive in the market. The actual results show that the packing department worked 2200 hours while 1000 kinds of cotton were packed. It is a very important tool for management as it provides the management with a very close look at the efficiency of labor work.

Examples of indirect labor include wages paid to the production supervisor or quality control team. While they are a part of the production process, it would be difficult to trace these wages to the production of a single desk. Indirect labor is included in the manufacturing overhead category, not the direct labor category.

The actual costs and quantities incurred for direct materials, direct labor, and variable manufacturing overhead are reported in Exhibit 8-1. Since direct labor hours are the cost driver for variable manufacturing overhead in this example, the variance is linked to the direct labor hours worked in excess of the standard labor hours allowed. This overage in direct labor hours means that $22,500 of additional variable manufacturing overhead was incurred based on the standard amount applied per direct labor hour. Inefficient use of the cost driver used to apply variable manufacturing overhead typically results in additional overhead costs. The total direct materials variance is calculated as the total standard costs allowed for direct materials of $315,000 less the actual amount paid of $330,000 equal the total direct materials variance of $(15,000) U.